Which one? (Part V) – FLIR T Series for Electrical/Mechanical Applications

My epic blog series continues with Part V of Flir’s “How to Choose” video series; this installment focuses on the T series cameras and their benefits as applied to electrical and mechanical applications. If you have read my other post (and I will be greatly saddened if you have not…), you have a good idea of the features available thus far in Flir’s camera line. The T series (T420, T440, T620, T640) is the big daddy of the group, bringing it all into one and offering quite frankly the most advanced commercial thermal imagers available.

My epic blog series continues with Part V of Flir’s “How to Choose” video series; this installment focuses on the T series cameras and their benefits as applied to electrical and mechanical applications. If you have read my other post (and I will be greatly saddened if you have not…), you have a good idea of the features available thus far in Flir’s camera line. The T series (T420, T440, T620, T640) is the big daddy of the group, bringing it all into one and offering quite frankly the most advanced commercial thermal imagers available.

Flir recommends these cameras for frequent use, including applications that require multiple surveys daily, such as in a preventative maintenance program at a plant. A big part of what sets this series apart from the pack is the optical block that houses the lens, which rotates 120º, allowing you to view things at odd angles and overhead without having to contort yourself or the camera. This equals the most ergonomic experience you can get with a thermal camera which ultimately leads to more comfortable and productive work. Another big feature of the T series is the interchangeable lenses, which include a telephoto lens that is perfect for surveying far away objects like those involved in performing electrical substation surveys at a safe distance. On that note, the cameras offer auto focus and manual adjustment, with the T640 offering continuous auto focus.

As before, all the cameras feature wireless communication via wi-fi for streaming and mobile applications (report emailing etc.) as well as Bluetooth for Extech Meterlink meters, which allow you to imbed electrical data in your thermograms. Resolution, sensitivity, and range increase as you move up the models with the T640 boasting a huge 640x480 resolution (the highest commercially available) and a temperature range of 2000ºC.

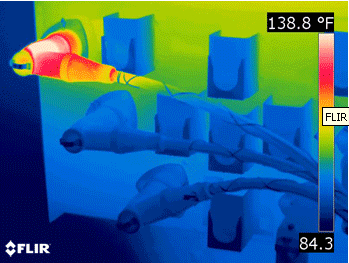

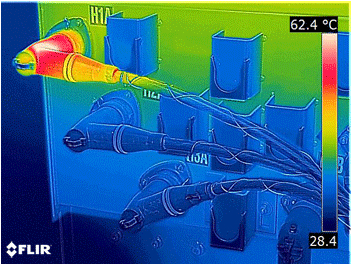

Now for the most exciting feature (in my opinion): MSX or Multi-Spectral Dynamic Imaging. This is Flir’s proprietary technology that goes a step beyond thermal fusion to etch digital image data onto your thermographic images in real-time. This provides sharp real world detail in addition to temperature measurements with results so clear that separate digital images are usually not needed in reporting. You can see to the right the difference between a normal thermal image and one that is MSX enhanced.

Now for the most exciting feature (in my opinion): MSX or Multi-Spectral Dynamic Imaging. This is Flir’s proprietary technology that goes a step beyond thermal fusion to etch digital image data onto your thermographic images in real-time. This provides sharp real world detail in addition to temperature measurements with results so clear that separate digital images are usually not needed in reporting. You can see to the right the difference between a normal thermal image and one that is MSX enhanced.

That’s all for now. The 6th and final entry in this blog series coming soon

Add new comment